November 2016 Microgrant Recipients: Where are they now?

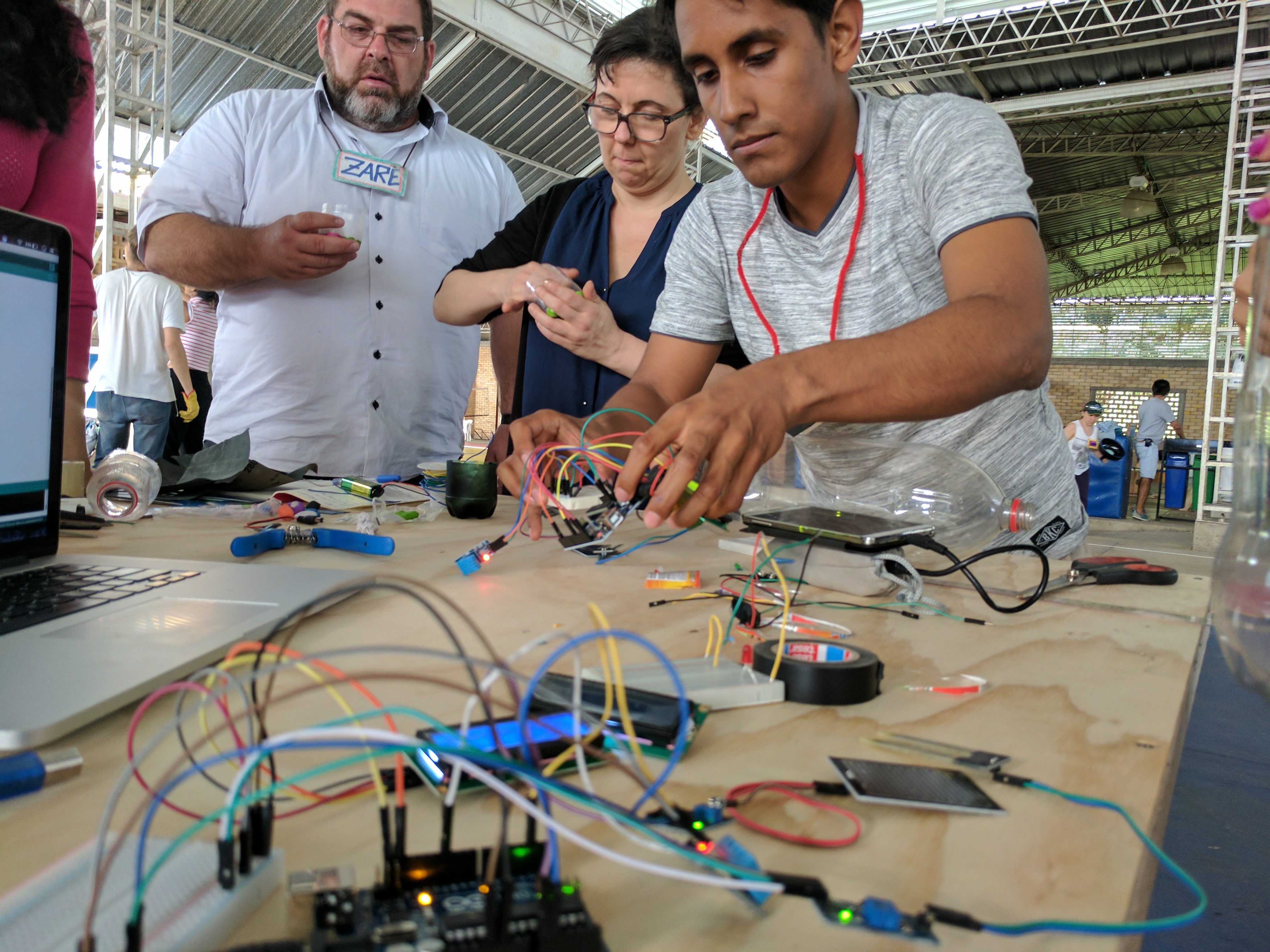

Participants at IDDS Climate Change Adaptation in Colombia iterate on the Low-Cost Weather Station, which received an IDIN microgrant in fall 2016.

Last fall, IDIN distributed one last round of microgrants, enabling IDIN Network members to prototype, test, or launch new innovations. So, what happened next? Here, the microgrant recipients share their accomplishments and the lessons they learned about co-creation, iteration, and entrepreneurship.

Terra Neeru, India

Terra Neeru is an integrated agriculture ecosystem design for water scarce regions in India, focusing on the production of cattle fodder through aquaponics.

With his IDIN microgrant, Abhinav Dey was able to build and test a proof of concept. His current aquaponics setup enables fish, corn, millet, pulses, and a variety of vegetables to be grown. The irrigation system ensures that a farmer's borewell has enough time to recharge, ensuring perennial harvest of all plants. The team has cultivated partnerships with other innovators addressing water scarcity in farming. This project is housed at the Project DEFY innovation center in Mangalore, enabling community members to regularly interact with and contribute to the design.

.png) In the coming months, the Terra Neeru team aims to develop an electronic data logger for water quality and plant health, pilot the system in four different farming contexts, and sell the system to their first customers.

In the coming months, the Terra Neeru team aims to develop an electronic data logger for water quality and plant health, pilot the system in four different farming contexts, and sell the system to their first customers.

Lesson Learned: “Managing team members by making challenging design briefs and giving them deadlines to solve, planning immersions for the same and building partnerships with local stakeholders and innovators.” – Abhinav Dey

Multifunctional Bici-Machine, Colombia

The low-cost Multifunctional Bici-Machine can perform many tasks with a single machine: milling grain, grinding stone, and even washing clothes. This machine can bring livelihood opportunities and time savings to families in Colombia without consistent electricity access.

Alex Freese built several iterations of the machine in the past months, developing mechanisms to adapt the machine to a variety of functions. Because different uses require different operating revolutions, connections, and heights, Alex tested several mechanisms to adjust gears, connectors and platforms to adjust to these needs.

Alex piloted the washing machine function at IDDS Climate Change Adaptation, where approximately 80 participants and organizers used it to wash their clothes during the 17-day summit. During this time, he collected valuable information about the machine’s performance and ergonomics.

Alex plans to disseminate the technology by teaching others to replicate the machine. Two communities from IDDS are interested in learning to build and disseminating it locally, and Alex plans to conduct workshops there in the coming months.

Lesson Learned: “The production of bicycles is not an exact science that can be easily documented.” – Alex Freese

Kiswa Cookstove, Uganda

Originally created at IDDS Cookstoves in 2016, the Kiswa Cookstove is a modified Lorena mud stove with a chimney, large firewood inlet, and two burners. At the end of the summit, the stove was installed in five homes.

Using the microgrant, Caroline Gabeya installed the Kiswa Cookstove at two additional households in Luttisi, Uganda in order to collect user feedback and conduct performance tests. She then collaborated with researchers at the Centre for Integrated Research and Community Development Uganda (CIRCODU) to conduct kitchen performance tests and water boiling tests to evaluate fuel savings and thermal efficiency.

Users reported they like the stove because it retains heat, uses less fuel, cooks with two pots at the same time, is safer, cooks faster, produces less smoke, and is inexpensive. They also raised some issues with the current prototype, including cracking and heat loss. The users also recommended that the stove height be reduced to enable the heat to quickly reach the pan while cooking. Caroline is working on these improvements and is working with the community chairman to attract more interest in the stoves.

Lesson Learned: “It is important to always test a prototype and make sure it works well before launching it in a community.” – Carolina Gabeya

Rainwater Harvester, Uganda

To combat drought in Pader, Uganda, Denis Obwona built an improved rainwater harvesting technology that is portable and easy to dismantle and reassemble. It includes a 12,000-liter storage tank for irrigating a vegetable garden.

With the microgrant, Denis was able to complete the construction of the storage tank, rain harvester sheet, and mounting stand. The system has been installed in the vil lage of Amokolagwai and is undergoing testing. He is still building the irrigation component of the system.

lage of Amokolagwai and is undergoing testing. He is still building the irrigation component of the system.

He plans to open a public demonstration site and learning facility to promote rainwater harvesting at the household level. He is also working with the local district government and local youth to promote adoption, and he will continue to develop they system at the Tet Centre in collaboration with the local IDIN Uganda chapter in Pader.

Lesson Learned: “With collaboration things that may look difficult and impossible can be made possible. The rainwater harvesting innovation could have been impossible without collaborative support from the local youth, land owners, water engineer and IDIN.” – Denis Obwona

Sigiri LowCO Jiko, Uganda

The Sigiri LowCo Jiko stove was first developed at IDDS Cookstoves in 2016 in Uganda to reduce carbon monoxide emissions. The stove reduces emissions by 25-30%, reduces fuel consumption by 40%, and reduces cooking time by 10-15%.

Using the microgrant, Jackson Mutegeki continued to iterate on the summit prototype. He developed four different prototypes and evaluated each for safety, emissions, and fuel savings in partnership with CIRCODU, choosing the best design based on performance and feedback. He also gathered feedback from ten different users and continues to iterate the design based on their recommendations. He now plans to introduce his design to the Biomass Energy Efficient Technology Association (BEETA), so that other stove manufacturers in Uganda can incorporate the design principles while manufacturing their stoves. He is working closely with bioenergy students at Nyabyeya Forestry College to produce and market the design.

Lesson Learned: “I have learnt how to engage the stove users in the development of stove design (co-creation). The users know how they want a product to look like. It is not good to decide for them yet you are designing for them.” – Jackson Mutegeki

Deep Sand Wheelchair, Zambia

Originally designed at IDDS Botswana in 2016, the Deep Sand Wheelchair uses wider, more durable wheels and levers to enable wheelchair riders to move through sand and gravel terrain.

Using the microgrant, John Nambwa produced an improved wheelchair prototype and has continued to develop accessories for the wheelchair at the Kafue Innovation Centre. He is working closely with the local District Hospital and Ministry of Health, the local Community Development Agency, as well as an organization called Tubaluba, which does mobility work in Kafue. In the coming months, he hopes to become certified as a wheelchair service provider.

Lesson Learned: “I have learned working on the prototype needs someone who is passionate and patience for it needs a lot of making and breaking for it to reach a working prototype.”

Disinfecting Toilet Seat, Zambia

The Disinfecting Toilet Seat improves sanitation in public and shared toilets in Zambia by reducing germ load and odors. It discharges a disinfectant aerosol mist consisting of a disinfectant, fly repellent and aroma.

Over the last six months, Joseph Chipyoka developed a cost-effective manufacturing process and material, created a business plan with the Zambia Development Agency, and developed a distribution model through chain stores with a presence in informal urban communities. They are now awaiting certification from the Zambia Bureau of Standards and Environmental Council of Zambia. In the meantime, they have demonstrated the product at technology fairs and door-to-door.

Lesson Learned: “The most important lesson learnt has been the approach needed to be used in product evaluation keeping in mind the benefits it delivers, for whom are the benefits and how to develop a viable business around said beneficiaries.” – Joseph Chipyoka

Low-Cost Weather Station, Colombia

The Low-Cost Weather Station monitors and records weather and climate data for farmers in Colombia. It is built using Arduino and sensors for temperature, air and soil humidity, pressure, rain, and gas concentration. The cost of the current station is $25, much lower than the $200-300 stations available on the market.

Using the microgrant, Juliana Garcia Sarmiento built an Arduino-based prototype to measure air temperature, air humidity, soil humidity and rainfall, featuring an external casing made from a soda bottle. She brought the prototype to six communities in and around Fusagasugá, Colombia, where IDDS Climate Change Adaptation took place. Before and during IDDS, she obtained feedback and suggestions from the community. The team also developed close relationships with the Tierra Libre farm, where they will continue to travel to collect feedback and make modifications.

The prototype was also integrated into IDDS Climate Change Adaptation as a Build-It, where participants added their own modifications, including radio data transmitters and other types of sensors. Using these ideas and the community feedback, they are continuing to make improvements so that the product will take up less space, have fewer breaks in connectivity, and connect with other stations. They plan to disseminate the technology by carrying out workshops at the C-Innova innovation center in Bogotá.

Lesson Learned: “It is important to go and visit the communities to know the real problems and to get more information and feedback.” – Juliana García Sarmiento

Bee Propolis Healthcare Products, Kenya

Bee Propolis Healthcare Products are a range of natural healing salves that provide alternative income to beekeeping farmers in Kenya. These products use bee propolis extracted from beehives, to make medicinal ointments as well as health foods.

With the microgrant, Juliet Wanyiri’s team has worked on improving the propolis prototypes, including a healing salve and a honey infused with propolis. They identified suppliers of the raw beeswax from beekeepers in Baringo, Kenya, and they engaged the Kenya Beehive Association to access lab facilities for prototyping, product testing and development. They have carried out in-house research with the team on the  extraction of propolis and the preparation of the propolis tincture using alcohol.

extraction of propolis and the preparation of the propolis tincture using alcohol.

They are exploring a variety of dissemination channels, including online sales, local pharmacies and healthcare stores in Nairobi, and open pop-up markets. Going forward, they are looking into quality control for small-scale manufacture.

Lesson Learned: “The importance of maintaining quality each of the raw materials so as to achieve a consistent final product. This was true both in the type and quality of propolis that we sourced as well as in the ethanol used during the maceration process - both of these variables affect the end product and should keep at a standard.” – Juliet Wanyiri

Biodigester, Colombia

July Carolina Rojas Gómez has developed a low-cost biodigester to provide affordable cooking fuel to the community of San Antonio. The biodigester uses organic material to produce biogas and biofertilizer through an anaerobic process that decomposes the organic material and generates methane and carbon dioxide for cooking.

In the last six months, she has built a total of six biodigesters for six families in San Antonio, who became interested after seeing the functional prototype. Over that time period, she has visited to monitor the performance of the biodigesters, collect user feedback, and identify other interested community members. Going forward, she hopes to develop a sensor mechanism to measure the quantity of gas produced and used, and she hopes to transfer the technology to other communities.

Lesson Learned: “People in the countryside are willing to implement new technologies, and especially if they are low cost, but they won’t risk it until they see an example of it working.” – July Carolina Rojas Gómez

Mobile Broiler Housing Unit, Zambia

Kenneth Mubuyaeta has built a mobile, easily-to-assemble housing unit suitable for poultry producers of between 50 to 100 birds per batch. The slated floor and raised design separates the birds from their droppings and increases airflow, minimizing disease.

After building the first prototype out of wood, Kenneth partnered with a women’s group in Kafue to test the unit with one brood of 75 hens. He reached out to the District Livestock and veterinary offices, whose staff visited to evaluate the unit on disease prevention, manure disposal and cost-effectiveness. With this feedback, he designed and constructed a second prototype primarily out of metal.

Livestock and veterinary offices, whose staff visited to evaluate the unit on disease prevention, manure disposal and cost-effectiveness. With this feedback, he designed and constructed a second prototype primarily out of metal.

Kenneth has begun marketing the unit to cooperatives and has secured three orders. He has also connected with a vegetable producers group interested in chicken manure for use in their vegetable production enterprises as well as a biogas production project promoting the use of biogas stoves fueled by household waste and animal manure. Finally, he has developed partnerships with a poultry researcher to help test the units further and develop them commercially.

He hopes to disseminate the technology through NGOs working on malnutrition, and plans to follow up with the Ministry of Community Development.

Lesson Learned: “Many farm businesses fail to make headway because the levels of technology adoption are very low. Most of them are scared of leaving their comfort zones where they have been stuck on certain technologies, and many businesses are skeptical to invest in agriculture because of the many uncertainties prevalent in the sector.” – Kenneth Mubuyaeta

Mobiticket, Kenya

Mobiticket is a bus booking service for smartphone and USSD. Through the Mobiticket service, passengers can view available buses, fares, and sets for a given dates for different bus companies, and purchase tickets via mobile money.

In the last six months, Nickson Nyakambi and team migrated Mobiticket from beta testing to a full utility product. Mobiticket entered into a strategic partnership with M/s Jambopay, a Kenyan payment gateway service provider. In this partnership, Mobiticket services are integrated into Jambopay’s existing smartphone application. Mobiticket has also acquired its own dedicated USSD short code for SMS users. They have been reaching out public service vehicle operators through savings and credit cooperatives (SACCOs) and advertising their services on these vehicles. Since launch, their user base has increased to 35,000 people.

Mobiticket participated in the i2i Data Hack for Financial Inclusion, where they won both the Kenyan round and the final round in Kigali, Rwanda ($20,000). They were also selected for incubation and seed funding from the Safaricom Foundation Tech for Good Accelerator.

Lesson Learned: “Sourcing funds from sources especially from financiers originating from different countries can be really challenging and takes long. All the same, any partnerships and investment is a matter of trading off fear of risk with some element of trust and optimism.” – Nickson Nyakambi

Khidmatgaar.org, Pakistan

Khidmatgaar.org is a web platform that captures, communicates and tracks needs in specific larger emergency situations such as droughts, floods, earthquakes and attacks, so that willing volunteers can respond accordingly.

The microgrant enabled Sacha Ahmed and her team to conduct a simulation, a focus group discussion, and an ideation session with around 30 target users of the platform. (You can check a description of their simulation and design process here.) Through this event, as well as discussions with academics involved in resource coordination, they were able to gain an understanding of design requirements needed for the platform and gain critical feedback from target users.

The most likely dissemination strategies are either an open-source tool that allows local adaptation and adoption, or uptake by NGOs in Pakistan.

Lesson Learned: “Users perceive the platform as especially useful when it comes to long-term projects, such as patients that have lost their livelihood during an emergency and require financial support for an extended amount of time.” – Sacha Ahmed

Water ATM, Pakistan

Umair Anwar’s team at Information Technology University has developed the Water ATM, a stand-alone water quality measurement and dispensing unit that attaches to a water filtration plant to dispense a fixed daily quota of water to registered users. The amount of water dispensed to each user and water quality data can be monitored remotely on a centralized dashboard.

The team has developed two versions is currently working on developing a third version that is more robust and efficient. They are having conversations with local water officials as well as private water purification companies to install the device at existing filtration plants. The team plans to sell these companies a monthly subscription plan for the dashboard, where companies can monitor in real time the quality and amount of water dispensed. Once the team has figured out how to reduce the cost of the device, they plan to create Water ATMs (Automated Teller Machines) for registered users to collect water directly.

In June, they were awarded research grant of $374,599 through the Pakistan-United States Science & Technology Cooperation Program, which is made up of USAID, the United States Department of State, and the Higher Education Commission of Pakistan. Using these funds, they hope to hire a web developer and electric engineer, boosting the development process and accelerating toward the pilot phase.

Lesson Learned: “This project gave me a good chance to improve my product design and development skills and to enhance my confidence to interact with the government personnel.” – Umair Anwar